3D Printing, also known as additive manufacturing, is a revolutionary technology that has the potential to transform various industries. It is a process of creating physical objects from a digital 3D model by laying down successive layers of material until the object is created in its entirety. This process is significantly different from traditional manufacturing methods that involve subtractive processes like cutting or drilling.

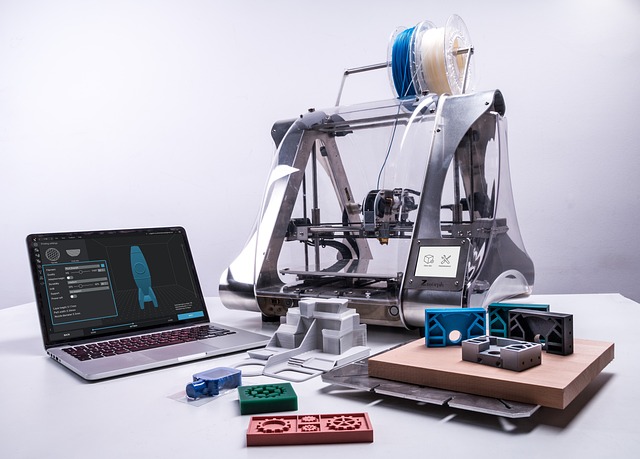

The process of 3D printing begins with the creation of a digital 3D model using Computer-Aided Design (CAD) software or a 3D scanner. The CAD software allows users to design and visualize the object they want to print. Alternatively, a 3D scanner can be used to create a digital model by scanning an existing physical object.

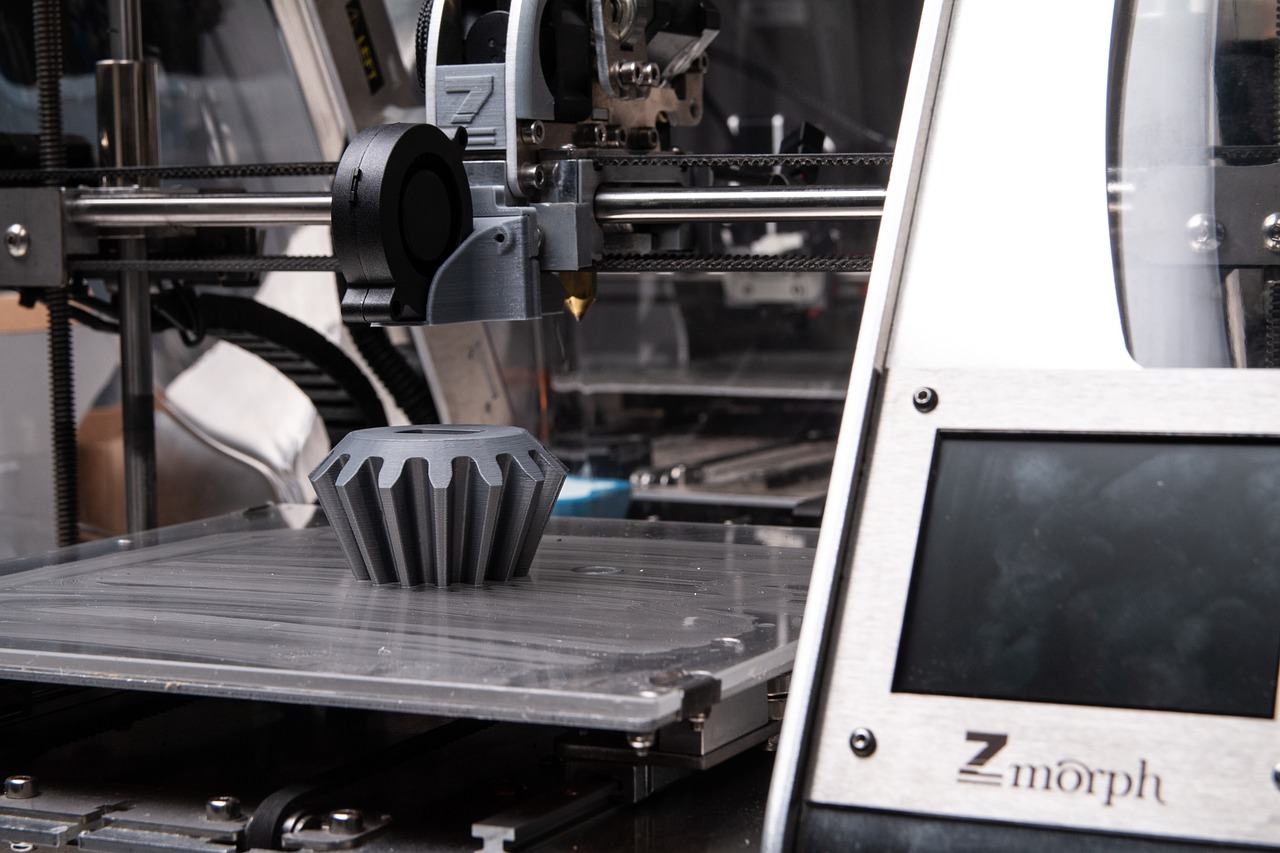

Once the digital model is ready, it is sliced into multiple cross-sectional layers using slicing software. Each layer is then sent to the 3D printer, which reads the instructions and starts building the object layer by layer. The printer deposits material, such as plastic, metal, ceramic, or even biological material, in precise locations based on the instructions from the digital model.

There are several types of 3D printing technologies available, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Each technology has its own advantages and limitations, such as printing speed, level of detail, material compatibility, and cost.

3D printing technology offers numerous benefits across various industries:

One of the major advantages of 3D printing is its ability to quickly create prototypes. Traditional manufacturing methods involve time-consuming tooling and setup processes, which can delay the development of new products. With 3D printing, designers can create a physical prototype directly from their CAD model in a matter of hours or days, allowing for rapid iterations and design improvements.

3D printing enables customization on a whole new level. Each object can be easily modified to meet specific requirements without the need for expensive retooling. This ability is particularly valuable in the medical field, where customized prosthetics, implants, and orthopedic devices can be directly printed to fit individual patients.

While the initial cost of a 3D printer can be significant, the potential cost savings over time can be substantial. Traditional manufacturing often involves a long supply chain, including transportation, inventory, and warehouse costs. With 3D printing, objects can be printed on demand, reducing inventory and minimizing waste. Additionally, the ability to produce complex designs using less material can lead to cost savings on material consumption.

3D printing is an additive process, meaning that materials are only added where they are needed. Unlike subtractive manufacturing methods, where excess material is cut away, 3D printing produces little to no waste. This makes it a more environmentally-friendly manufacturing method and contributes to a more sustainable future.

1. Manufacturing and Prototyping: 3D printing is widely used in manufacturing industries to create prototypes, tooling, and parts. It allows for faster design iterations, reduced lead times, and increased flexibility.

2. Healthcare: 3D printing has revolutionized the medical industry by allowing for the production of custom implants, prosthetics, surgical models, and organ-on-a-chip devices for drug testing.

3. Automotive: Car manufacturers use 3D printing for rapid prototyping, customization of parts, and even creating entire vehicle prototypes.

4. Aerospace: The aerospace industry benefits from 3D printing by producing lightweight aircraft components, reducing fuel consumption, and enabling complex geometries that were previously impossible to manufacture.

5. Architecture and Construction: Architects and designers use 3D printing to create intricate models and to explore complex designs. The construction industry is also exploring the use of 3D printing for building houses and structures more efficiently and sustainably.

While 3D printing has made significant advancements, there are still challenges to overcome. The speed of printing, the size of printable objects, and the availability of suitable materials are some of the barriers that need to be addressed for wider adoption.

However, as the technology continues to evolve, 3D printing has the potential to revolutionize industries by enabling decentralized production, reducing waste, and empowering individuals to create their own objects. With ongoing research and development, the future of 3D printing looks promising as it continues to push the boundaries of what is possible in manufacturing and design.